Diaphragm valves are essential components in various industries, providing reliable flow control in a wide range of applications. Understanding how a diaphragm valve works is crucial for anyone working with fluid or gas handling systems. In this article, we will discuss the anatomy, working mechanism, advantages, and applications of diaphragm valves, as well as their maintenance and troubleshooting.

Anatomy of a diaphragm valve

A diaphragm valve consists of four main parts: the body, bonnet, diaphragm, and stem. The body is the outermost part of the valve that houses the diaphragm and connects to the pipeline. The bonnet is the top cover of the valve body that houses the stem and provides a seal for the valve. The diaphragm is a flexible membrane that separates the valve body from the bonnet and controls the flow of the fluid or gas. The stem is a rod that connects the diaphragm to the actuator, which controls the opening and closing of the valve.

Types of diaphragm valves

Diaphragm valves come in different types based on their body and bonnet designs. The most common types are weir, straight-way, and tank outlet diaphragm valves. Weir diaphragm valves have a weir or dam on the body that directs the flow of the fluid or gas. Straight-way diaphragm valves have a straight body with an inlet and outlet for the flow. Tank outlet diaphragm valves are designed to control the discharge of fluids from tanks.

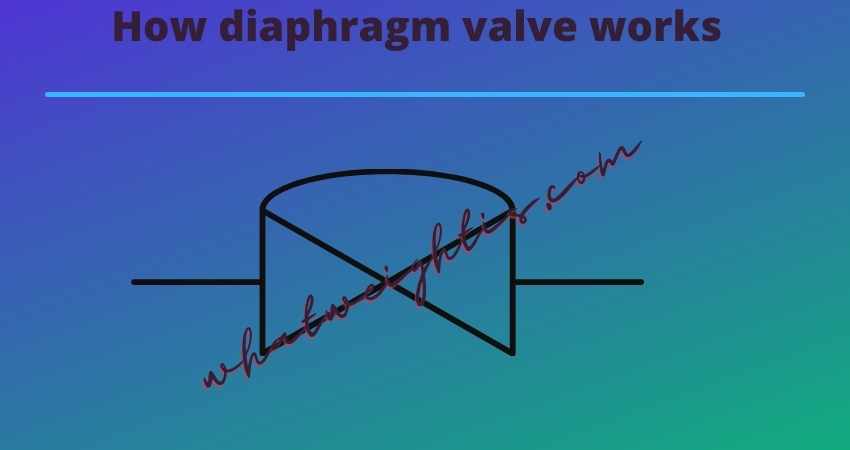

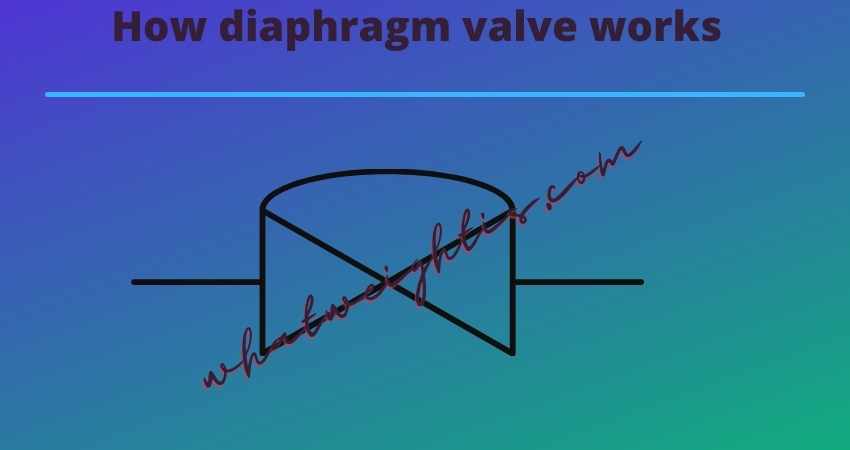

How a diaphragm valve works

A diaphragm valve controls the flow of fluid or gas by opening or closing a flexible diaphragm. When the diaphragm is open, the flow passes through the valve, and when it is closed, the flow is blocked. The stem is connected to the actuator, which moves the diaphragm up or down to control the flow. When the actuator pushes the stem down, the diaphragm is lifted off the valve seat, allowing the fluid or gas to flow. When the actuator pulls the stem up, the diaphragm is pressed against the valve seat, blocking the flow.

Advantages of diaphragm valves

Diaphragm valves offer several advantages over other types of valves. They are suitable for handling fluids and gases that are corrosive, abrasive, or viscous, as they do not have any metal parts that can corrode or wear out. They also provide a tight shut-off, preventing any leakage or contamination. Diaphragm valves are easy to operate and require low maintenance, making them cost-effective and reliable.

Applications of diaphragm valves

Diaphragm valves are used in various industries, such as pharmaceuticals, food and beverage, chemical, water treatment, and biotech. They are used in applications that require precise flow control, such as dosing, sampling, and filling. They are also used in applications that require sterile or hygienic conditions, such as in the production of vaccines and medications.

Maintenance and troubleshooting of diaphragm valves

Regular maintenance of diaphragm valves is essential to ensure their optimal performance and longevity. The diaphragm should be inspected regularly for wear or damage and replaced if necessary. The valve body and bonnet should be cleaned and inspected for any signs of corrosion or damage. Any leaks or blockages should be addressed immediately to prevent any damage to the valve or the pipeline.

In case of any issues with the valve, such as difficulty in opening or closing, or leakage, troubleshooting should be done to identify the root cause. The valve may need to be disassembled and inspected to identify the issue. Any damaged or worn-out parts should be replaced, and the valve should be reassembled and tested to ensure proper operation.

What are butterfly valves used for?

Conclusion

In conclusion, diaphragm valves are essential components in various industries, providing reliable flow control in a wide range of applications. Understanding how a diaphragm valve works is crucial for anyone working with fluid or gas handling systems. We discussed the anatomy, working mechanism, advantages, and applications of diaphragm valves, as well as their maintenance and troubleshooting. By following proper maintenance and troubleshooting procedures, diaphragm valves can provide long-lasting and reliable service, making them a cost-effective solution for fluid and gas handling systems.

Mr. Jahangir Alam is an Electrical & Electronics Engineer with a wide range of experience in several fields of Engineering. He finds engineering articles to be very interesting, and that is why he likes to write them. To know more about him, please click here.